Accessories: Flex bars

Thanks to the use of different flex bars (spiral, round grooved or non-grooved) the abrasive material will be optimally broken, and a constant flexibility of different materials can be achieved.

- Home

- Material overview

- Flex bar types

- Flexing principle and flexing samples

- Configuration possibilities

The material overview is a simplified indication. With our flex bars all common materials can be flexed and there are various combinations possible (Material table as pdf).

Very sensitive, light materials

- Spiral flex bar type 47258.

Light materials

- Spiral flex bar type 47235.

- Round grooved flex bar type 3036.

- Round grooved flex bar type 3015363.

Medium materials

- Spiral flex bar type 47235.

- Spiral flex bar type 47216.

- Round grooved flex bar type 30412.

- Round grooved flex bar type 30416.

- Round grooved flex bar type 3015363.

Heavy materials

- Spiral flex bar type 47216.

- Round grooved flex bar type 30416.

Very heavy materials

- Round grooved flex bar type 30536.

Fiber

- Round grooved flex bar type 30536.

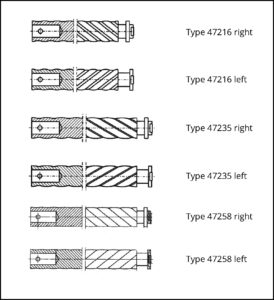

Spiral flex bars

Spiral flex bars

- Type 47258

Special version for very sensitive/light materials.

Set consisting of 4 pieces (2 right, 2 left). - Type 47235

Standard version for light up to medium materials.

Set consisting of 4 pieces (2 right, 2 left). - Type 47216

Standard version for medium up to heavy materials.

Set consisting of 4 pieces (2 right, 2 left).

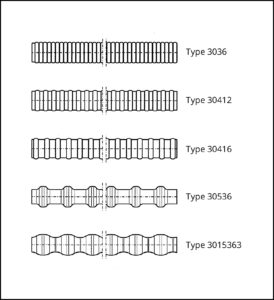

Round grooved flex bars

Round grooved flex bars

- Type 3036

Standard version for light materials. - Type 30412

Standard version for medium materials. - Type 30416

Standard version for medium up to heavy materials.

Also used instead of the spiral bars as a complete set of 6 bars. - Type 30536

Standard version for heaviest materials (also fiber).

Used as a set consisting of 5 bars type 30536 and 1 bar type 3036 at the end. - Type 3015363

Special version for light/medium materials.

Also used instead of spiral bars in a complete set of 6 bars. - Round/non-grooved

Standard diameter of 25 mm (30 mm on request).

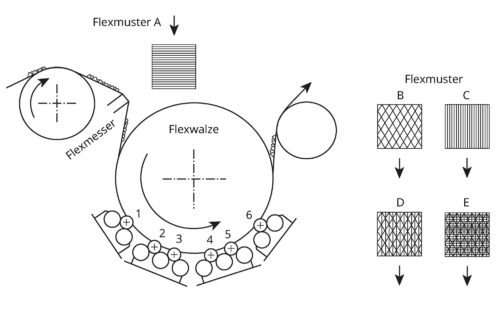

Flexing principle flexing machine type FCK and flexing machine type FCS

Description of flexing samples

Single flex (A)

The material is broken at 90° to the running direction.

Tool to be used: flex knife and non-grooved flex bars.

Double flex (B)

The material is broken at +40° and -40° to the running direction.

Tool to be used: spiral flex bars.

L-flex (C)

The material is broken in the running direction.

Tool to be used: round grooved flex bars.

Combiflex, trible flex (C)

The material is broken in the running direction and at +40° and -40° to the

running direction.

Tool to be used: round grooved flex bars and spiral flex bars.

Combiflex, quadruple flex (E)

The material is broken in the running direction; at +40°/-40° to the running direction

and at 90° to the running direction.

Tool to be used: flex knife, round grooved flex bars, spiral flex bars and

non-grooved flex bars.

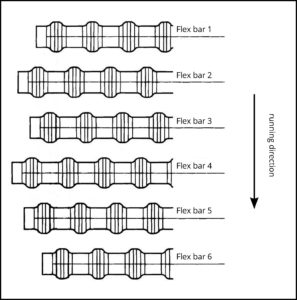

Configuration possibilities

The configuration possibilities showed are examples. There are various flex bar configurations possible.

Example 1

Layout: 6 flex bars of the same type (e.g. type 30536).

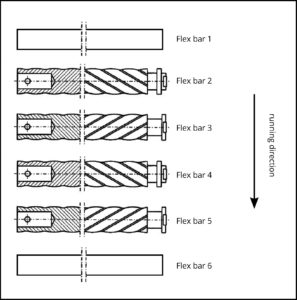

Example 2

Example 2

Layout: 1x non-grooved flex bar at inlet, followed by 2×2 spiral flex bars (e.g. type 47235) as well as 1x non-grooved flex bar at outlet.

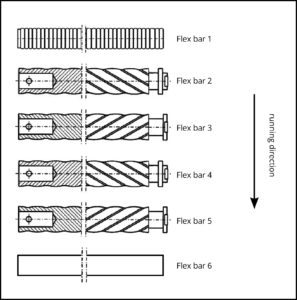

Example 3

Example 3

Layout: 1x round grooved flex bar at inlet (e.g. type 3036), followed by 2×2 spiral flex bars (e.g. type 47235) as well as 1x non-grooved flex bar at outlet.

How may we help you?

Contact us! Our experts will be happy to support you.

Tel. +41 52 720 70 30

info@amackerschmidag.com