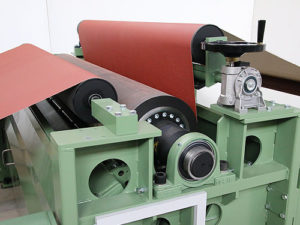

Flexing machine type FCS for jumbo rolls

The flexing machine type FCS enables highly efficient flexing of flexible and coated jumbo rolls with standard widths of 1650 mm, 1850 mm and 2150 mm. With our long-term proven and space-saving flexing system an optimal flexing effect can be reached (diagonally, longitudinally and in cross direction).

With the precisely adjustable flexing pressure and the different flex bars, all common materials can be handled

- Standard roll width 1650 mm, 1850 mm, 2150 mm.

- Unwinding and rewinding for rolls up to ø1400 mm.

- Variable speed drive 8 … 80 m/min.

- Rubber coated flex cylinder of approx. ø320 mm.

- Built-in spiral flex bars and round grooved flex bars of your choice.

- Element construction (unwinding / flex cell / rewinding).

- Several options available like humidification system, length slitter, automatic web tension, splice table … .

- Unwinding and rewinding for rolls up to ø1400 mm.

- Pneumatically adjustable unwind brake (automatically or manually).

- Unwinding with various systems possible:

– with square shaft 40/40 mm

– with square shaft 32/32 mm

– with pneumatically expandable unwind shaft for cores with ø75 mm, supported in two safety chucks. - Rewind drive with electronic torque control (600 Nm as standard, up to 1000 Nm available on request). Reversible, for winding with grain outside or inside.

- Rewinding with various systems possible:

– with square shaft 40/40 mm

– with square shaft 32/32 mm

– with pneumatically expandable unwind shaft for cores with ø75 mm, supported in two safety chucks.

Options:

- Automatic edge guiding system.

- Automatic and contactless brake control type AV depending on roll diameter.

- Easily replaceable rubber coated flex cylinder (approx. ø320 mm).

- Easily changeable flex bars in a large choice (round grooved, spiral or non-grooved flex bars)

- High-precision control of contact pressure for each flex beam individually.

Options:

- Knife flex device in front of the flex station for cross direction flex.

- Automatic edge guiding system.

- Automatic and contactless brake control type AV depending on roll diameter.

- Knife flex device in front of the flex station for cross direction flex.

- Built-in humidification system.

- Length measuring device.

- Splice table with manual cross cutter for splicing two jumbo rolls or for easier feeding of the material from the second roll.

- Automatic web tension by load cells.

Length slitter

- Length slitter for knife holder type KK.

- 2 knife holders type KK-25-F (simultaneous operation).

- 2 trim-cut winders up to a maximum width of 150 mm.

- Further information can be found on the separate flyer for knives, knife holders and fixed knife sets.

Flex cylinder with knife flex for flexing machine type FCS

Lateral removal of the flex bars (the flex bars can also be removed from above)

Video

Flex bars

Further information for flex bars.

How may we help you?

Contact us! Our experts will be happy to support you.

Tel. +41 52 720 70 30

info@amackerschmidag.com