Topseller machines

Home »

The machines listed below are available right away from stock.

Your benefits at a glance:

- Available right away from stock.

- New machines recently produced.

- Swiss quality.

- Spare and wear parts supply guaranteed.

- Comprehensive service and support.

Interested?

Contact us for further detail. It would be our pleasure to submit an offer or answer your questions.

E-Mail: info@amackerschmidag.com

- Roll width up to 1650 mm (maximum working width 1600 mm).

- Unwind station for rolls up to ø700 (larger diameters on request).

- Crush cut with mechanical knife holder system type KK for single knife holders as well as with fixed knife sets.

- Variable speed drive approx. 50 m/min.

- Built-in cross cutter.

- Main drive approx. 2.2 kW.

- Cutting pressure is pneumatically adjustable.

Brake and web tension are manually adjustable. - Rewind station for rolls up to ø400 mm.

- For very fine up to extremely coarse materials.

- Press force adjustable up to approx. 4500 N.

- Maximum joint length 400 mm (joining table).

- Active press width (belt) 40 mm, press roll width 45 mm.

- Minimum belt length with 90° joint angle = 250 mm

(270 mm are recommended for a comfortable handling). - Built-in heating up to approx. 80 °C.

- Up to 10 belts per minute (depending on operator’s efficiency).

- Single speed drive approx. 0.1 m/sec (variable speed drive is optionally available).

- Working height 1100 mm.

- Automatic knife guiding system based on belt edge detection.

- Wave cut function.

- Cut end automatic type SEA.

Time-controlled cut end automatic to stop the cutting process when working with several identical belts.

Especially suitable for high quantities of small/short belts. - Short belt stretcher to cut belt from 310 mm to 1800 mm.

- Maximum working width up to 360 mm.

- 5 mechanical knife holder KK-15-F.

- Machine color Blue RAL 5023.

- Standard electric supply 400V – 3ph – 50 Hz.

(other on request)

- For belts up to 460 mm width.

- Up to approx. 9 cuts (depending on the material) over the full width or up to approx. 12 cuts within 300 mm from the chassis.

- Cutting cylinder is axially movable.

- Knife system KK for knife holder type

KK-25-F / KK-15-F as well as for fixed knife sets. - Two speed drive

(approx. 0.6 m/sec and 1.2 m/sec)

with frequent converter. - Horizontal belt stretcher.

With automatic belt guiding system for long belts.

Including stretcher for belts up to 6 m.

Minimum belt length 1200 mm. - Short belt stretcher (ø45 mm) with hand-operated belt guiding.

For belts of 480 … ≈ 1800 mm.

Including hand wheel for precise adjustment of belt position. - Cut end automatic type SEA

Time-controlled cut end automatic to stop the cutting process when working with several identical belts. Especially suitable for high quantities. - 5 mechanical knife holder KK-25-F

- Machine color green RAL 6011.

- Standard electric supply 400 V – 3 ph – 50 Hz.

(other on request)

- Two-speed drive.

(approx. 0.05 m/sec and 0.1 m/sec) - Perfect for the production of non-woven materials (up to 6 mm).

- Length 6000 mm with inserting stretch 500 mm.

(extension of inserting stretch on request) - Material is passing through with grain side up or down.

(for tape joints and overlap joints) - Easy adjustable scuffing and gluing aggregates.

- Simultaneous preparation of both lap ends possible when producing long belts.

- 2 aggregate type D, for skiving the grain with a diamond cup wheel from the top.

- 1 aggregate type C, grinding and scuffing with an abrasive belt from the top.

- 1 aggregate type P, pointing or scuffing with an abrasive belt, or a wire brush.

- 2 glue spray head type LS (working from the top).

- 2 meter drying stretch type T (working from the top).

- 1 automatic tape applicator type FAS/L.

The tape is automatically applied and finalizes the procedure with a flush cut. - Machine color green RAL 6011.

- Standard electric supply 400 V – 3 ph – 50 Hz.

(other on request)

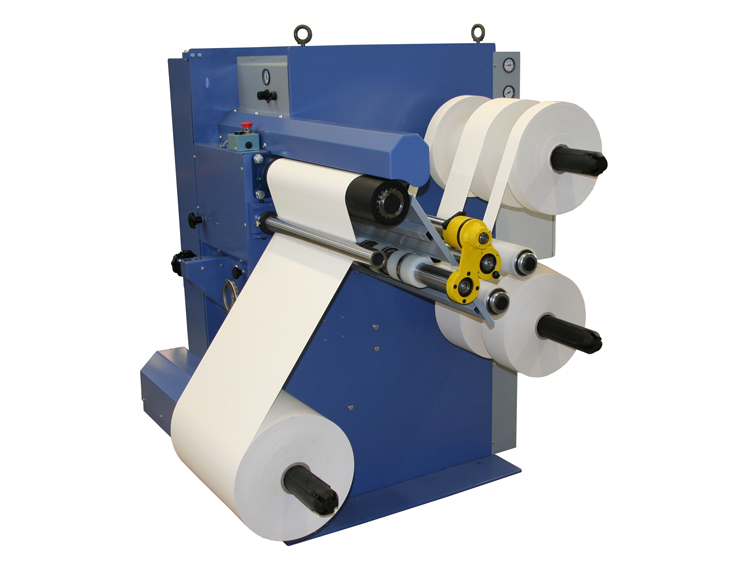

Cut-to-length machine type HTBP

- Maximum cutting length 500 mm.

- Pneumatic cutting.

- Shear cut system for straight cuts (no wave cuts possible).

- Cut with dished knife against „throw-away“ blade.

- Cutting angle adjustable between 90° and 45°.

- Machine can be turned on its pedestal.

- Working height 910 mm.

Unwind station type TVK

- Automatic partial feeding type TV through the cutting machine.

- Unwinding with pneumatically expandable unwind shaft as well as mechanical brake.

- For rolls up to 620 mm width.

(working width 610 mm) - Unwind station for rolls up to ø600 mm.

- Crush cut with mechanical knife system KK or fixed knife set.

- Pneumatically adjustable cutting pressure.

(max. 4000 kp) - Rewind station for rolls up to max. ø400 mm.

- Web tension is separately adjustable for both shafts.

- Pneumatically expandable shafts for unwind station and rewind station.

- Variable speed drive up to approx. 60 m/min.

- Reversible rewind drive for winding with grain outside or inside.

- 5 mechanical knife holder KK-25-F.

- Machine color green RAL 6011.

- Standard electric supply 400 V – 3 ph – 50 Hz.

(other on request)

- For rolls up to 620 mm width.

- Shear cut system

- Variable speed drive up to approx. 90 m/min.

- Unwind station for rolls up to ø750 mm.

- Rewind station for rolls up to max. ø500 mm.

- Web tension is separately adjustable for both shafts.

- Pneumatically expandable shafts for unwind station and rewind station.

- Without edge guide unit.

- 5 upper and lower shear cut knife holder.

(minimum cutting width 15 mm) - Machine color Blue RAL 5023.

- Standard electric supply 400 V – 3 ph – 50 Hz.

(other on request)

Punching machine type SSZ

- For rolls up to ø600 mm.

- Discs of ø90 … 300 mm.

- Shear cut punching tools.

- Punching tools are exchangeable.

- Discs/sheets with or without center hole as well as with or without suction holes.

- Foot operated punching.

- No electric power needed.

- Pneumatic pulling device type V,

with adjustable range of 80 … 310 mm (for scrap web). - Pneumatic preselecting counter type PZ,

to stop the machine after the pre-selected number of cuts is reached. - Machine color green RAL 6011.

- Compressed air of 6 bar.

- Machine for punching discs up to ø225 mm of flexible and coated abrasives.

- Crush cut system and directly from narrow rolls.

- Unwinding with fixed shaft and 2 board discs.

- For roll widths up to 320 mm and a maximum roll diameter of 600 mm.

- For discs with a maximum diameter up to 225 mm.

- Maximum cutting force 250 kN (25 t).

- Punching performance approx. 16-20 discs/minute with single-layer punching

(depending on disc diameter, material and feeding length).

Up to 3 time higher with multi tool and multi-layer punching. - Adjustable penetration depth of the blades (steps of 0.05 mm).

- Continuously adjustable cutting force with hand wheel.

Digital display in bar (15 … 120 bar). - Counting automatic

(endless counting up or counting down with automatic stop). - Adjustable feeding system 80 … 300 mm.

- Two-hand control for safety reasons during setup of the machine as well as for

the adjustment of the punching tools (cutting depth and cutting pressure). - Collecting tray for the punched discs.

- Collecting tray with removable drawer for punching waste like

center holes, suction holes etc. - Ejector cylinder for pushing the punched material into the collecting tray.

- Automatic rotation of the punching support to reduce wear.

- Machine color green RAL 6011.

- Standard electric supply 400 V – 3 ph – 50 Hz.

(other on request)

How may we help you?

Contact us! Our experts will be happy to support you.

Tel. +41 52 720 70 30

info@amackerschmidag.com